Roof Hatch Solutions

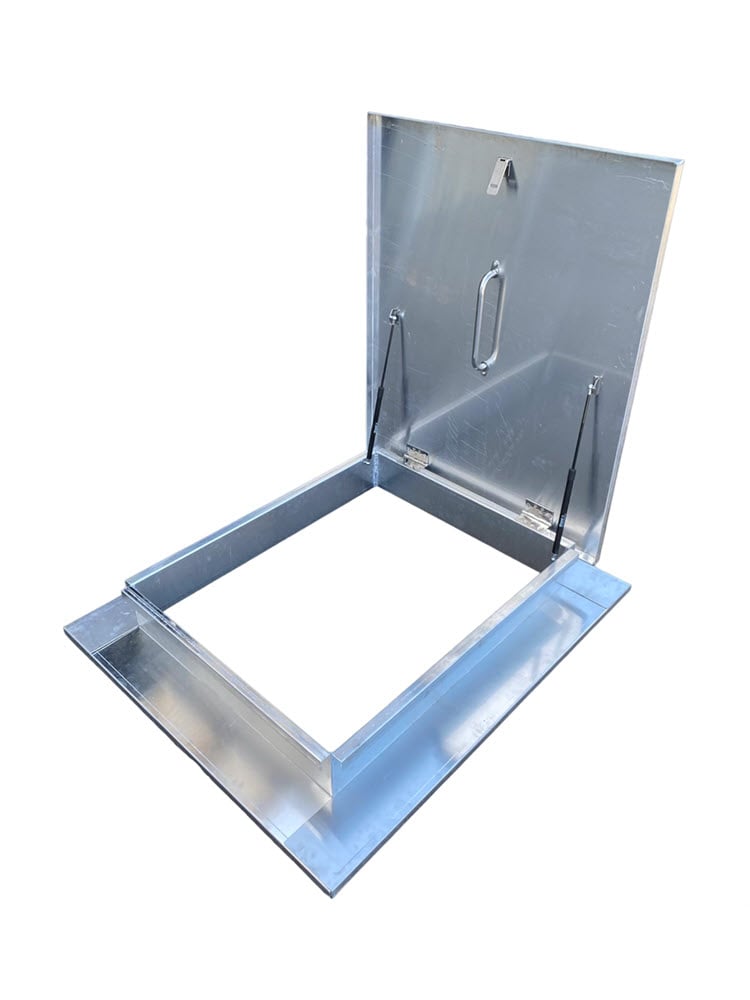

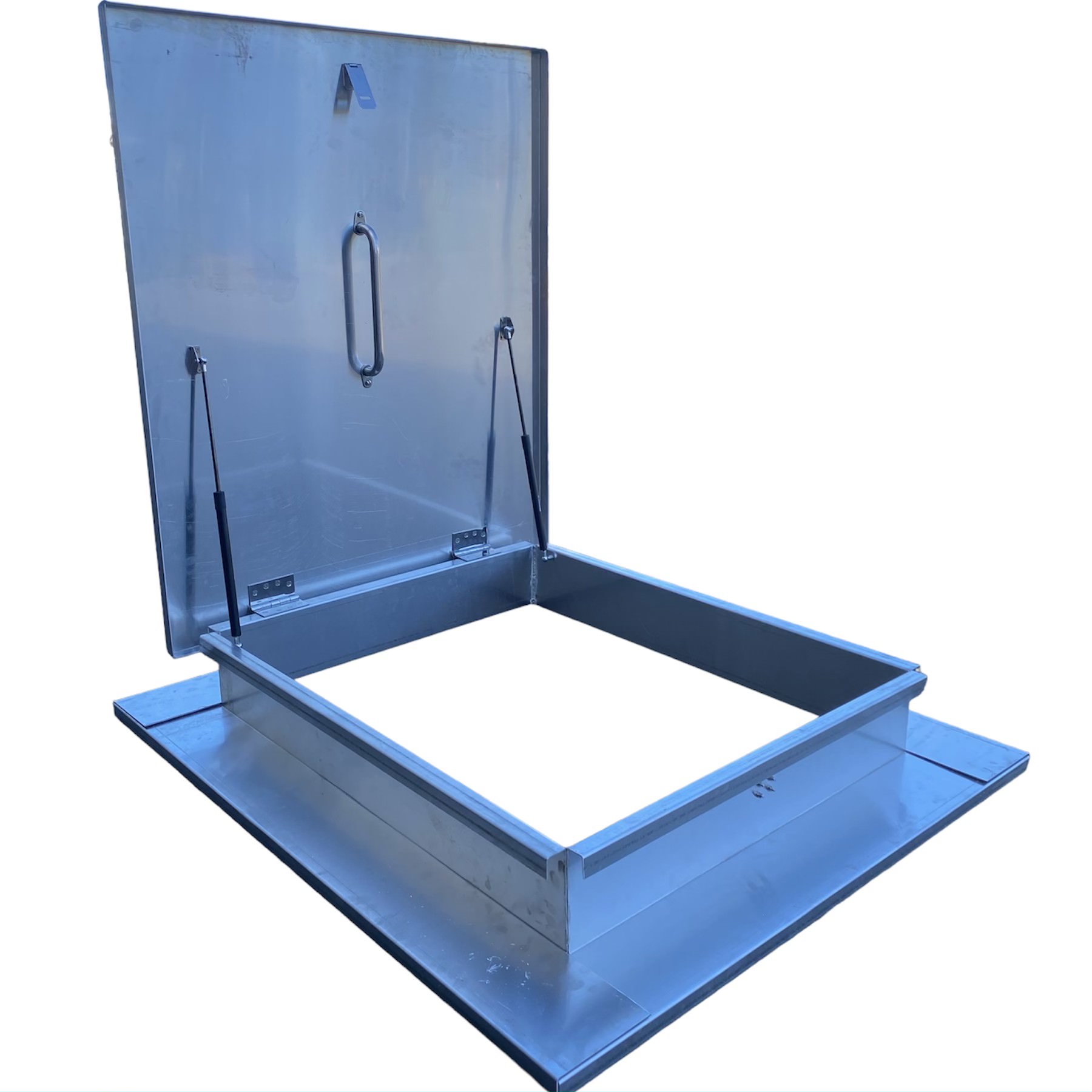

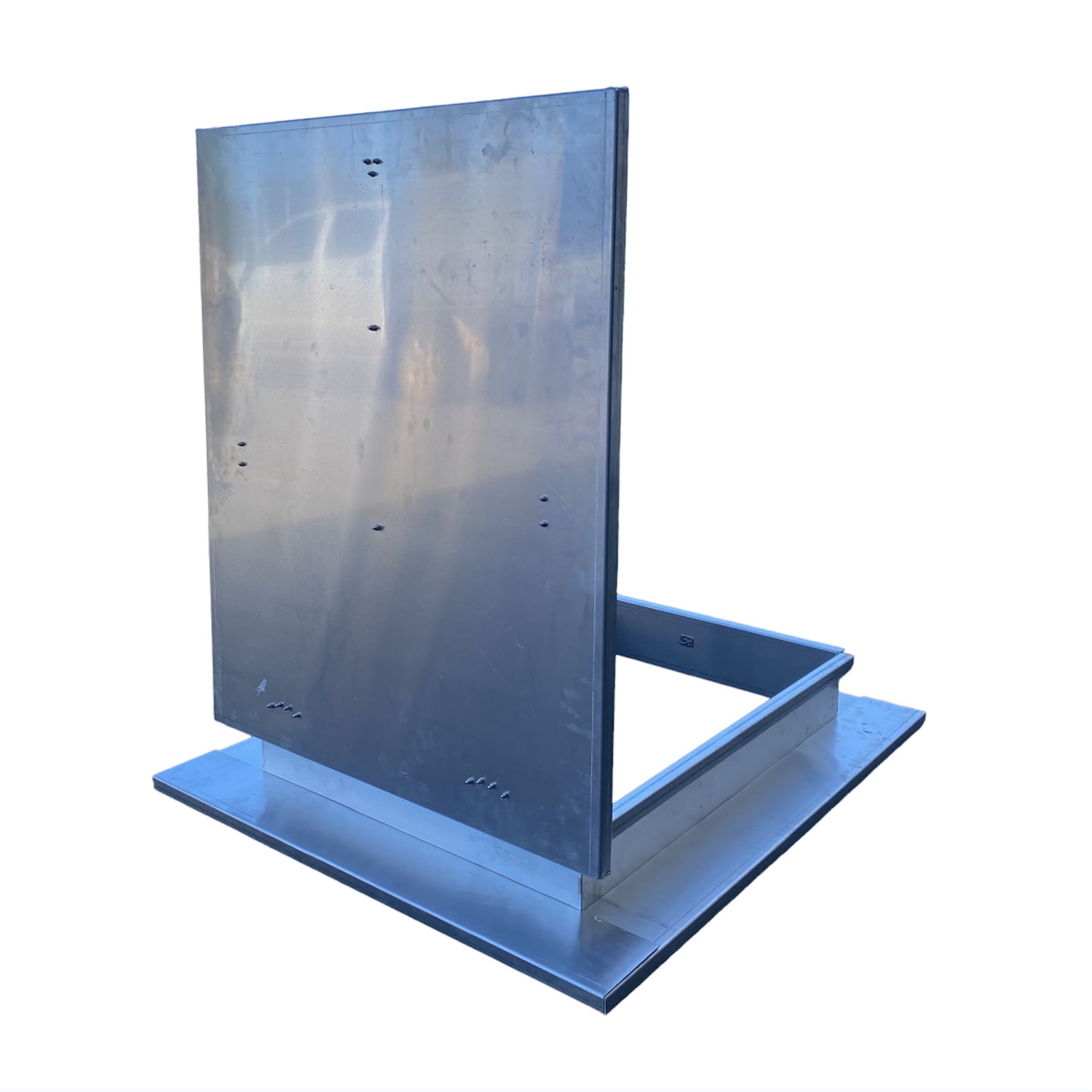

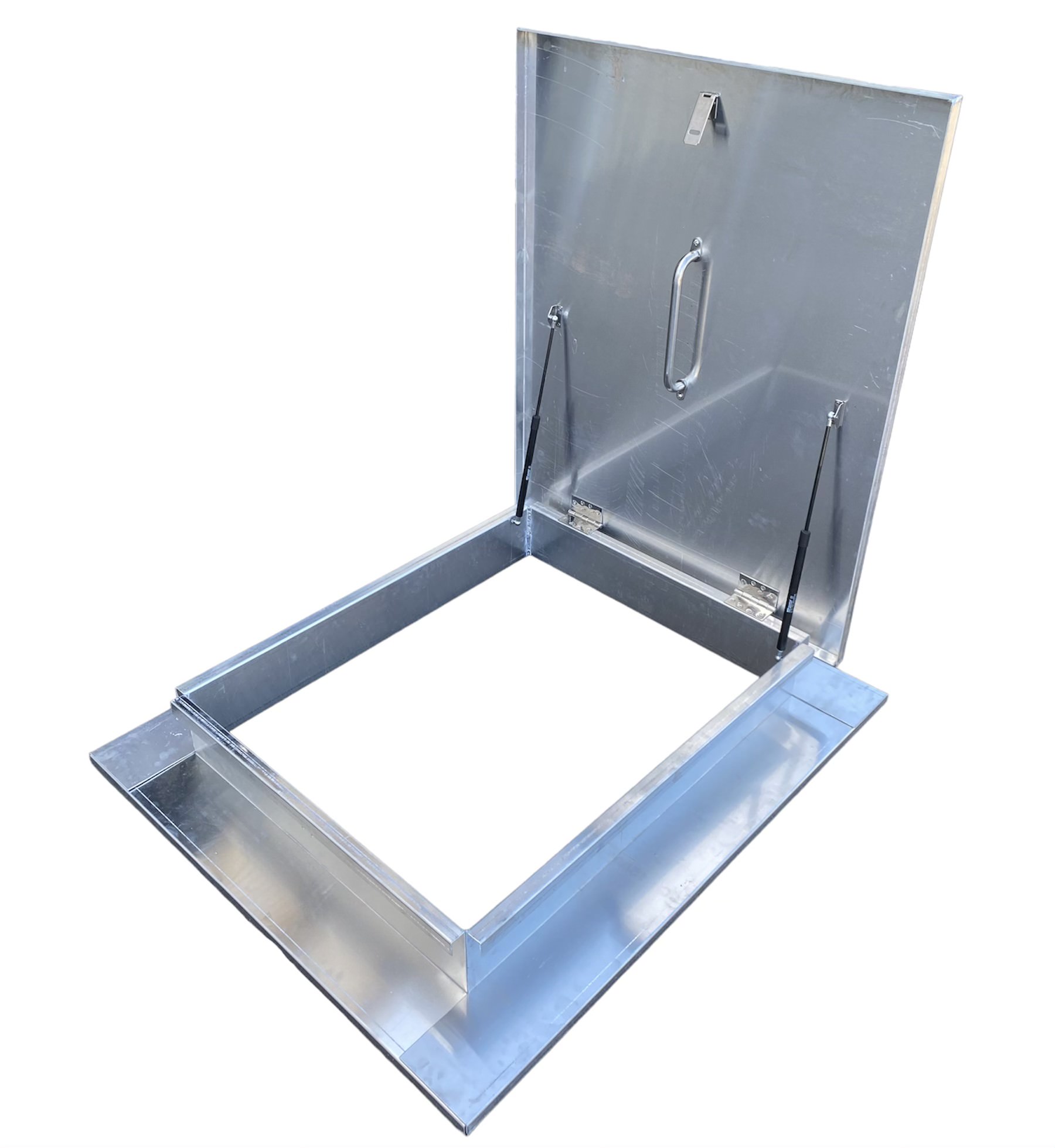

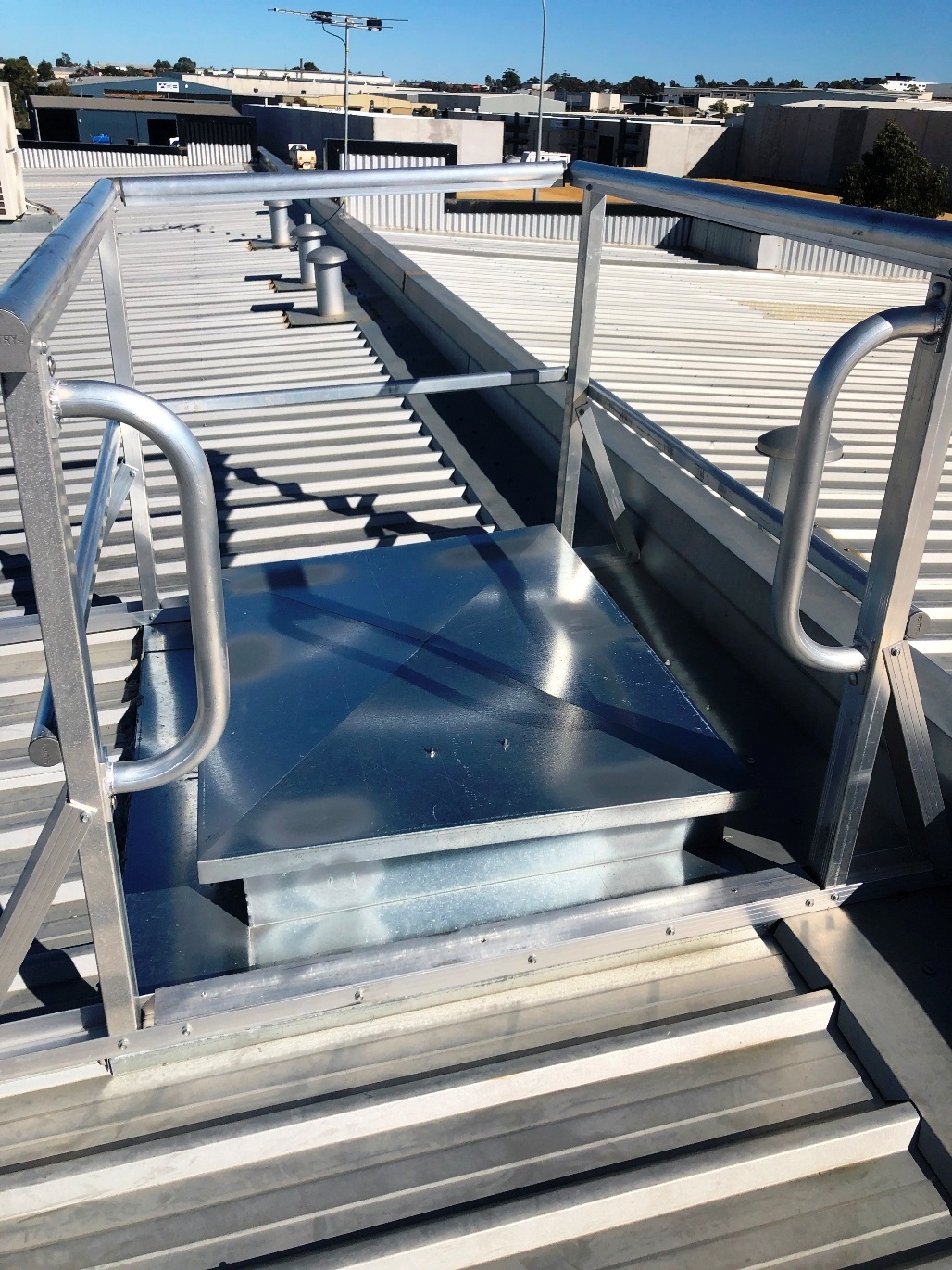

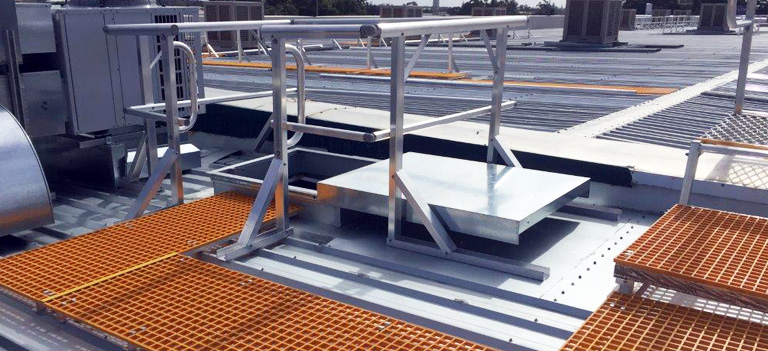

We provide custom made roof hatches to suit all situations using 2.5 mm Aluminium sheeting. Our hatches are rigid and manufactured to suit all roof profiles and environmental conditions.

We also fully trim out the roof structure under the roof hatch.

Powder coating can lessen the visual impact of a hatch helping it blend in with the building design.

Roof hatches can allow for greater security and flexibility in their position.

We recommend if the building is multi tenanted than the roof hatch needs to be located in a common area.

If your office has a busy floor plan and the roof space allows you can access through the manhole in one location and then via walkway access your roof hatch in a different location.

When installing roof hatch’s, we like to use Cover Flashings were possible, instead of the standard pop or soaker flashing. This is to further minimize any potential roof leak.

Frequently Asked Questions

Press the '+' icon below to read the answer.

What is a roof hatch?

What size roof hatch do I need?

Do I need guardrail around my roof hatch?

Do I require signage for my roof hatch?

All Roof Access WA installs comply with:

- AS/NZ 1891-1, 2, 3 & 4 - Fall Arrest Systems

- AS 1657-2018- Fixed Platforms, Walkways, Stairways and Ladders

- AS/NZS 4488 Parts 1 & 2: Industrial Rope Access Systems

- AS/NZS 1319 Safety Signs for Occupational Environment

- Worksafe - Code of Practice - Managing the risk of falls at workplaces